Materials – Technical guide

In the production of furniture and furnishing accessories the materials used are varied. The choice of a piece of furniture must bear in mind first of all the material of which it is composed, both for practical use and for aesthetic characteristics.

Below we have created a guide to help users choose the furniture or furnishing accessory based on the specific use and with reference to the technical and aesthetic characteristics for each type of material.

FRAME

Lacquered Metal

The lacquered metal frames are the result of lacquering carried out on steel to which the company has always reserved particular care and attention. The raw material composed of tubes and sheets of different thicknesses is folded, cut and ironed to give it the desired shape.

Each frame undergoes a degreasing and oven-drying bath. Ready to be transported in the lacquering cabin, it is sprayed with gaseous jets of electrostatically charged epoxy powder paint.

This allows the paint to adhere perfectly to the surface.

The application of this powder is carried out, depending on the models, either by robot or manually by dedicated operators.

Subsequently the products are transported in the baking oven where the powder applied will melt with the steel guaranteeing resistance over time.

Chrome Metal

Chrome metal is a decorative process carried out with a polished nickel electrodeposition and a subsequent application of a chrome flash. It gives the structure a shiny, mirror-like appearance that remains unchanged over time. It is a decorative treatment with high surface hardness and high rust resistance

Wood

The wooden structures are made of solid wood. The epoxy painting is carried out with the totally ecological water method thanks to the absence of chemical solvents.

The procedure involves two phases:

- The first one that gives color to the wood grain from which the different finishes are born

- The second totally transparent guarantees protection both to the dye and to the wood fiber from humidity and UV rays.

TOP

Melamine

The top is made of pressed wood particles coated on both sides with a thin thick decorative paper.

Main features:

- Low price

- ABS edging made with industrial methods using hot-melt glue in the same color as the top

- The finishes guarantee continuity of color without changing over time

- Good scratch resistance

Unicolor

The Unicolor tops are made of particle board panels plated on both sides with resistant laminate sheets.

Laminates are obtained from:

- Back composed of multiple layers of phenolic paper

- Laminated sheet with decorative print

- External protective layer

The pressing of these elements gives the top:

- Resistance to wear, impact, abrasion and water infiltration

- The laminate edges give the top aesthetic harmony and greater resistance to humidity and infiltrations

- Hygienic and easy to clean

Fenix Laminate

Fenix laminate is an innovative material obtained with the aid of nanotechnologies that allow to treat the surface with last generation acrylic resins, hardened and fixed.

This treatment gives the material properties out of the ordinary:

- Fenix regenerates from micro-scratches thanks to heat-repairability

- Super matt surface, anti-fingerprint and pleasantly soft touch

- Resists wear, abrasion, shocks and solvents even more than unicolor

- ABS edging made with industrial methods using hot-melt glue in the same color as the top

Lacquered Wood

All lacquered wood tops are made with epoxy powder coated MDF panels.

Powder coating is an innovative process and represents an ecological alternative to painting with traditional enamels with which excellent performance is achieved both in terms of finish and sealing.

The MDF panels have the advantage of being:

- Fireproof

- Water repellent

- Suitable for lacquering and routing

Each top in epoxy powder-coated MDF is oven dried twice and this makes

- The final lacquering is more homogeneous and scratch-resistant compared to normal painting

- The surface thus obtained has good resistance to daily use

Wood Veneer

Veneered tops are made by covering an MDF support with wood sheets. The wood sheets are obtained by sectioning tree trunks and for this reason there are no perfectly identical plans to each other.

The sheets are applied to the MDF support by gluing with polyurethane resins and then lacquered with transparent acrylic paint to ensure a protective layer.

Veneered tops are produced with different thicknesses to perfectly match the model on which they are offered.

They are available in finishes that easily match with all day environments of modern design.

Solid Wood

The wood used in the tables is selected among the best existing in the European and American markets. All the woods chosen for the production of solid wood tables undergo a drying process that goes from a minimum of 6 months to 8 in order to reduce the humidity to 5%.

This is the best way to obtain a stable wood that, although alive, suffers as little as possible from changes in the external temperature

The presence of ” knots” and variations in color tones between one table and another testify to the authenticity and uniqueness of each individual plant. The woods are sectioned into boards coupled together to make up the top. Under each floor sheet metal reinforcements are housed to ensure greater stability of the boards over time.

The boards used for the long outer edge are left with the original shape of the tree trunk that gives the true natural effect. Each outdoor table is cleaned from the bark by hand giving the floor uniqueness and craftsmanship.

All the tops are treated externally with a water-based paint that gives homogeneity to the touch and protection from moisture infiltration.

Veneer with edge in Solid Wood

This special top combines the aesthetic performance of solid wood with those of veneered tops. The outer edge of the top is in fact made of real solid wood selected from the best existing in the American and European markets. The long sides with an irregular shape are shaped with a radius that simulates the radius of the trunk.

The entire floor is glued to a sheet of fine wood that allows it to look like a real solid floor.

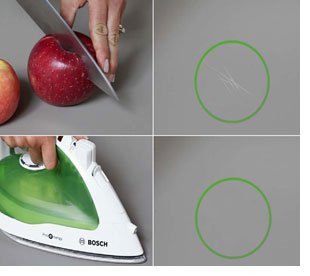

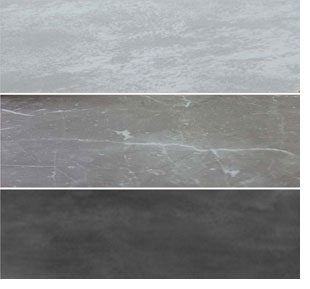

The Super Tops: Superceramic – Supermarble – Supercement

The Super tops are born from the combination of Float Glass and Porcelain Stoneware. Porcelain Stoneware is a laminated porcelain with very high surface resistance.

Resistant to chemical attacks, organic solvents, inorganics, disinfectants, detergents, scratches, deep abrasion.

Its properties remain unaltered even after intensive use and frequent cleaning. Thanks to an average water absorption of 0.1% it is also resistant to frost and adapts to all indoor and outdoor weather conditions.

Resistant to UV rays and the colors remain unchanged in the presence of any condition. Totally compatible with food substances, it does NOT allow the onset of fungi, bacteria, molds.

Extremely easy to clean it can be assimilated as a resistance to coatings commonly used for flooring.

Resistance to heat at high temperatures (it is possible to place hot pots or iron)

- Hygienic and antibacterial

- Scratchproof

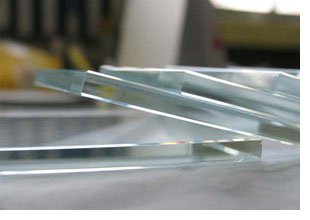

Crystal tops

The glass tops are versatile and able to take on a different personality depending on the environment in which they are inserted thanks to the different finishes proposed in the range.

All crystals are generally hardened

Tempering is a special heat treatment that increases its characteristics in terms of mechanical resistance and thermal shock. In the event of breakage, thanks to this treatment, the tensions are released instantly, causing the glass to crumble into small harmless fragments.

You can find different types of crystals:

- POLISHED CRYSTAL

- TRANSPARENT CRYSTAL

- SMOKED CRYSTAL

- MATT CRYSTAL

Polished Crystal

In the lacquered glass tops the float glass sheets are coated with high quality paint that, treated thermally, is perfectly fixed to the top. The paint through these passages takes on a smooth, homogeneous and bright appearance, enhancing its aesthetic appearance and at the same time facilitating its maintenance.

Transparent Crystal

The transparent crystal thanks to its perfectly neutral color and allows a perfect return of the colors observed through the glass.

Smoke Crystal

It is a transparent crystal inside which there are some colored particles that give aesthetic and decorative features to the top. In this case it is a pleasant anthracite shade.

Matt Crystal

The matt scratch-resistant glass characterized by a strong resistance to scratches, abrasions and stains. The strong resistance is given by the production technology called “dynamic corrosion”

The surface of the anti-scratch crystal is treated with specific acids that allow the chamfering of the micro crests generated by the common acid etching.

The chamfering of the micro-chips avoids the appearance of scratches (a visible scratch is commonly the breaking of the micro-cracks) and facilitates cleaning from liquids (that is, it allows the liquid to slip away). Very easy to clean: the small surface marks are simply eliminated by passing a soft cloth. The matte finish makes the crystal warmer and more pleasant to the touch, “silk effect”, in line with current trends in contemporary furniture.

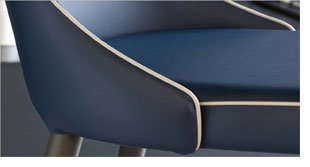

COATINGS

Premium Leather

The premium leather used in the upholstery of the chairs preserves the original and natural softness of the finest coats with high levels of aesthetics, touch and durability.

It is half grain cowhide with natural grain of variable thickness. The tanning is carried out with chrome and the passing dye allows to transfer the color to the skin over the whole thickness.

Ecological Leather

The ecological leather used in the coating is a synthetic leather capable of reproducing the look and feel of real leather.

It is a regenerated leather with a cotton backing that guarantees strength, impermeability, correct breathability at a highly competitive price.

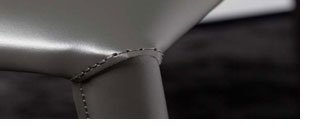

Leather

Obtained from the tanning of animal skin, the leather lends itself to use in the upholstery of the chairs for its aesthetic characteristics of resistance and hygiene.

The version of the leather chairs is embellished with contrasting stitching in contrast.

Wide range of colors to meet all matching needs.

Leather Fiber

The leather fiber is a material obtained from a transformation process that allows to obtain a coating very similar to animal leather at a competitive price.

Also in the leather fiber version it is possible to have stitching to match or contrast with the chosen finish.

Nabuk

Composed of microfibres coupled with cotton fabric. The Nabuk fabric offers an ideal covering for the upholstered seat.

The elegant suede effect is combined with the incredible water repellent effect that allows liquids to slide over the fabric without penetrating it. Nabuk fabric is totally fireproof.

Pure Virgin Wool

The brand guarantees the production with 100% natural textile fiber obtained from the fleece of animals. It guarantees solidity of colors and enriches the seat making it warm and welcoming.

Texplast

Texplast is a fabric composed of synthetic fibers with high performance especially in terms of resistance. Hygienic and easy to clean. In the chairs the texplast is heat-sealed and not simply sewn giving absolute resistance over time.

PLASTIC MATERIALS

Polypropylene

Polypropylene is a stable, comfortable and weather-resistant plastic material. It is mainly used for seats and accessories that can also be used outdoors.

The main features are:

- Extremely resistant

- Suitable for interiors, exteriors and contract.

- Recyclable and environmentally friendly

Polycarbonate

Polycarbonate is a thermoplastic polymer obtained from carbonic acid. Comfortable and weather resistant. It is mainly used for seats and accessories that can also be used outdoors.

The versatility of polycarbonate makes it an excellent product for creating functional products and at the same time a high aesthetic impact. It can be easily shaped and dyed different colors.

The main features are:

- Transparency

- Excellent resistance and stability

- Suitable for interiors, exteriors and contract